CASE STUDIES

January 10, 2021

CUSTOMER CREATIVITY

Situation

This case study shows that a customer may choose to design and build his/her own custom made fixture to be mounted on an air chuck.

In this case, a customer has purchased a PML-PAL turning chuck, a precision air chuck, 125mm, NBC type with three jaws, along with air feed tube, and three top jaws.

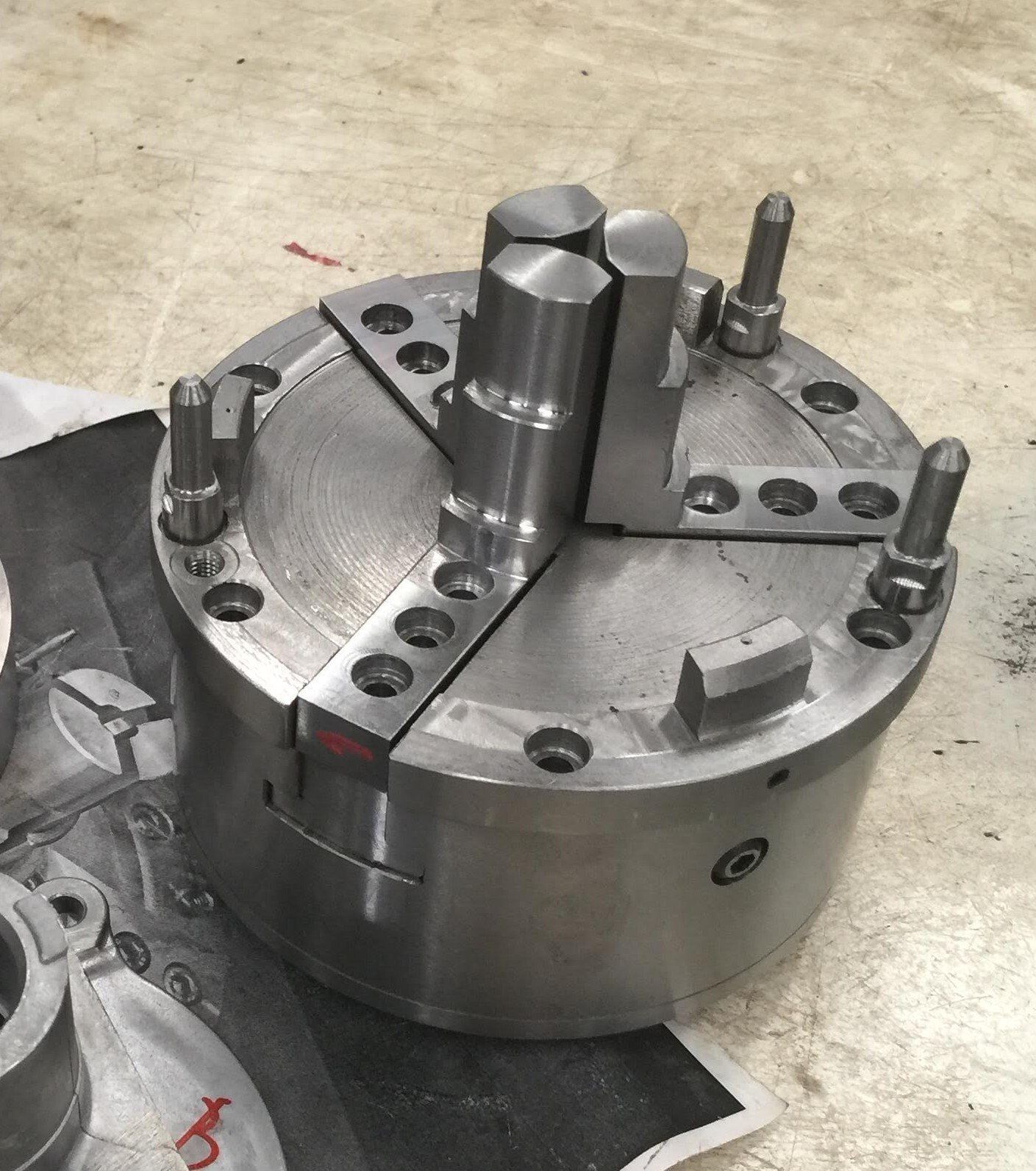

The customer has built a fixture/cover to go on top of the chuck’s

front side with three orientation pins, and three stoppers. He

prepared custom top jaws in order to mount the work piece. (See

photos below)

A chuck cover with orientation pins and stoppers

The customer prepared an adaptor for the air feed tube

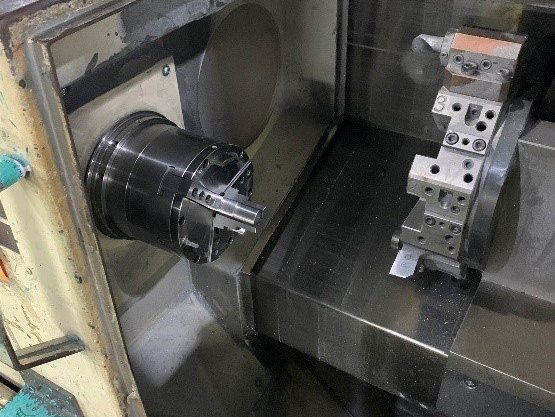

The chuck, including the fixture, is mounted on the machine