AIR CHUCKS

April 23, 2023

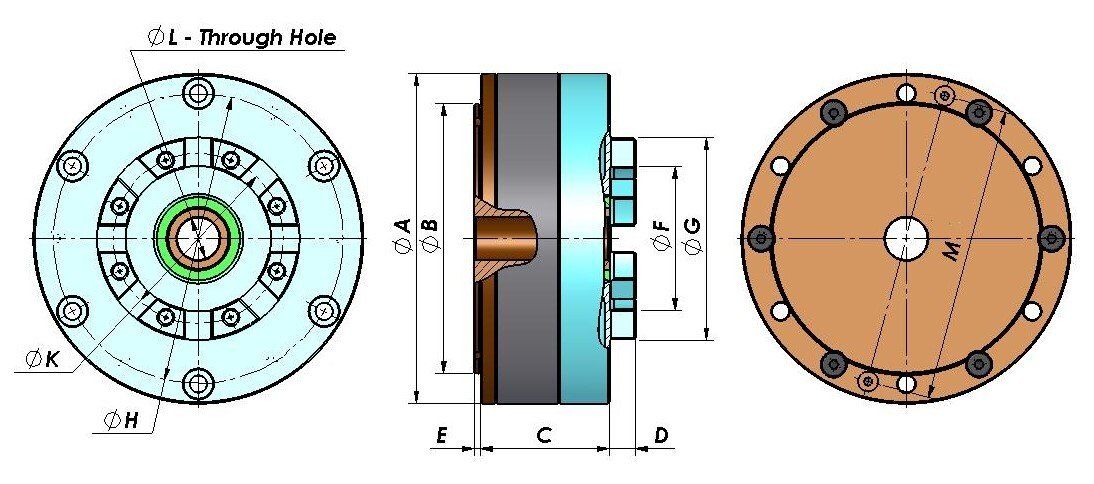

DIAPHRAGM AIR CHUCK

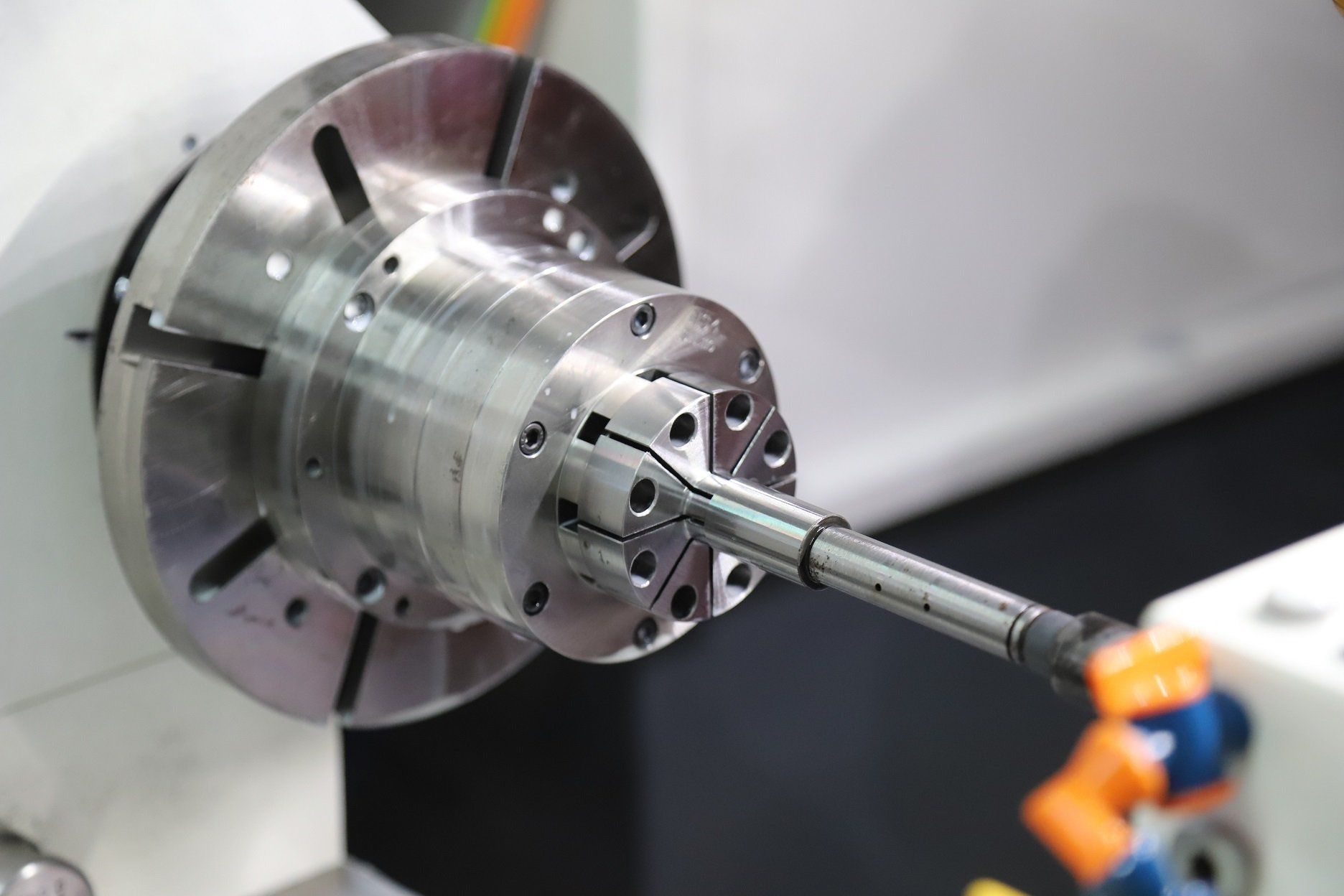

Diaphragm chuck is a sealed chuck used for super high precision work.

It provides almost absolute repeatability.

The chucks are mainly used in finishing applications, whether it is turning, grinding or milling.

Diaphragm chuck main features:

Repeatability – diaphragm chuck's repeatability is within 0.0005mm or 0.00002". It is guaranteed.

Stable Clamping – The work piece clamping is stable even over 8000rpm. Thanks to unique design, the jaws are not affected by the centrifugal force. Sub-micron accuracy and super fine finish are assured under high speed machining.

Flexible clamping power – In case of both, internal and external chucking, and the air pressure can be adjusted with great flexibility to the value which suits an application by an air regulator. This feature provides the mechanist the possibility to machine parts with “thin walls” without damaging or deforming the part dimensions.

Maintenance Free – The high precision diaphragm air chuck does not require lubrication. It is a sealed chuck. A unique design prevents penetration of cutting chips, swarf into chuck body. Thus, this DC is ideal for any CNC turning, vertical machining and precise grinding operation.

High Durability and Stability – Jaw and front cover are made of special materials which have been heat treated specifically to maintain rigidity and accuracy over the long term.

Flexible Application – This diaphragm chuck can accommodate both internal and external chucking. Back stops can be designed inside of the work piece, and outside as well by utilizing the external flange.

High Speed Turning Ability – The standard model can be rotated up to 8,000 rpm. A special faster model is available. It includes internal weights for counter balance system that allows spinning the chuck at more than 11,000rpm.

The high precision diaphragm air chuck size ranges from 80mm to 200mm or 3" through 8". Customer may have specific through hole size Diaphragm Chuck upon request (see on the bottom). Diaphragm tandem chuck is available in 100mm and 150mm or 4" through 6".

Through Hole Diaphragm

Technical Parameters in mm

| Model | # Splits | A | B | C | D | E | F | G | H | K | L | M |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DCQ 80 | 8 | 80 | 50.8 | 36 | 6 | 2.5 | 25 | 38 | 71 | 31.5 | 9 | 35 |

| DCQ4 | 6,8,9,10 | 101 | 82.55 | 39.5 | 8 | 2 | 44 | 62 | 88.9 | 52 | 16 | 90.5 |

| DCQ5 | 6,8,10 | 127 | 101.6 | 42 | 10 | 2.5 | 50 | 70 | 114.3 | 60 | 12-22 | 115 |

| DCQ5 | 6,8,10 | 127 | 101.6 | 50 | 9 | 2.5 | 55 | 75 | 114.3 | 65 | 23-27 | 115 |

| DCQ6 | 8,10 | 150 | 125 | 48 | 10 | 3 | 76 | 96 | 135.89 | 86 | 40 | 137 |

Standard Diaphragm

Technical Parameters in mm

| Model | # Splits | A | B | C | D | E | F | G | H | K |

|---|---|---|---|---|---|---|---|---|---|---|

| DC80 | 6,8 | 80 | 50.8 | 40 | 5 | 3 | 25 | 38 | 70 | 31.5 |

| DC4 | 6,8,10 | 101 | 82.55 | 39.5 | 8 | 2 | 44 | 62 | 88.9 | 52 |

| DC5 | 6,8,10 | 127 | 101.6 | 45 | 10 | 2.5 | 50 | 70 | 114.3 | 60 |

| DC6 | 8,10 | 150 | 125 | 41.5 | 10 | 3.2 | 60 | 80 | 135.89 | 70 |

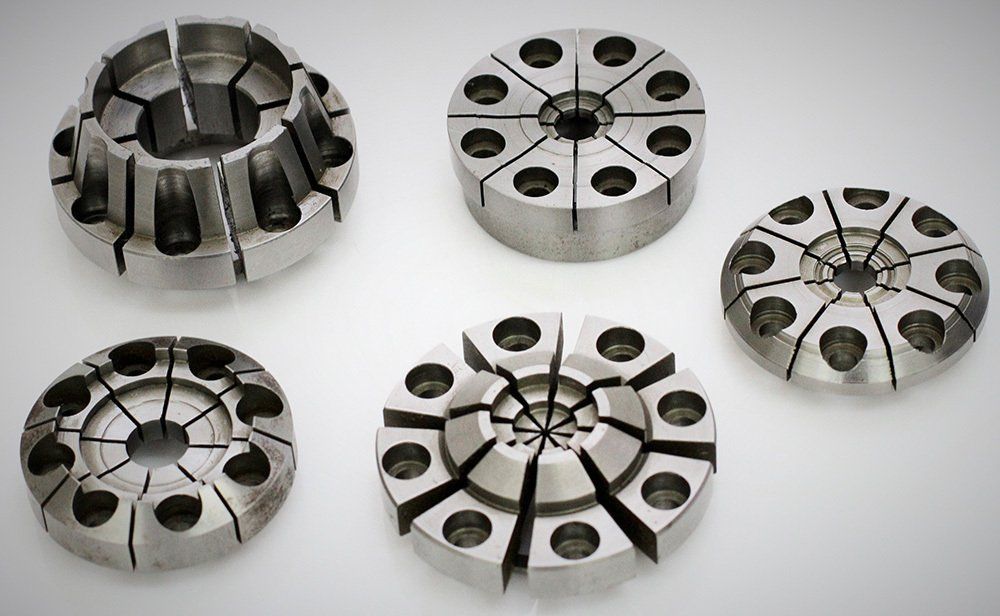

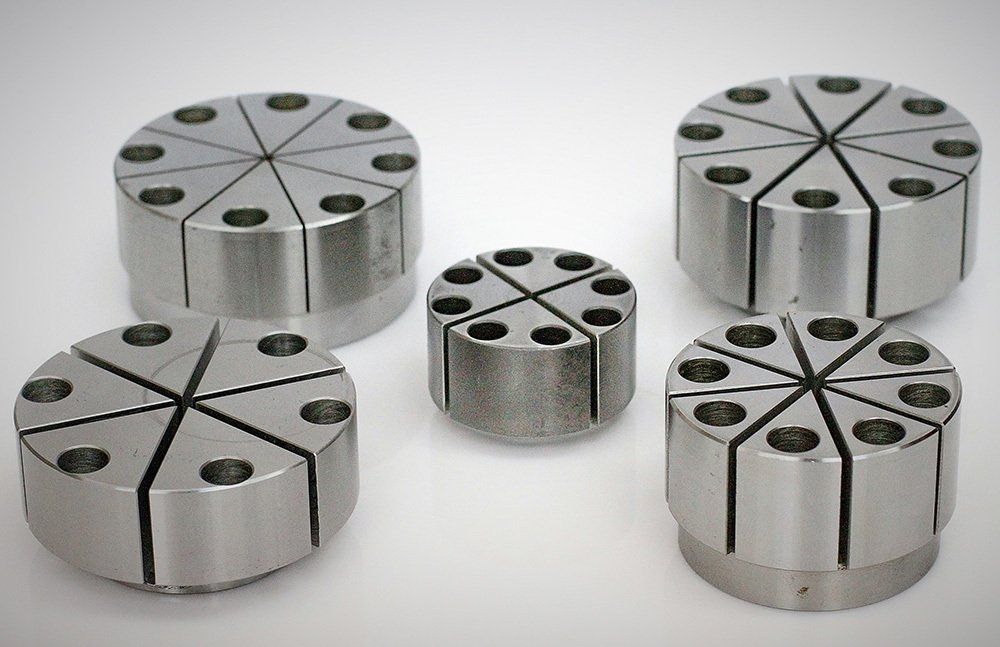

High Precision Diaphragm Chuck Jaws

PML-PAL produces top jaws. In addition, we also custom make or modify them per customer specifications. The jaws can be hardened and ground. Top jaws shape, the dimensions, and the material can be determined by the customer. Below are photos of top jaws, custom made or modified jaws, and inserts.

DC6-TH40 model - diaphragm chuck is a super high precision Ø150mm or 6"

with a Ø40mm through hole and top jaws.

DC5-TH20 model - diaphragm chuck super high precision Ø127mm or 5"

with a Ø20mm through hole without top jaws

DC5 model - diaphragm chuck super high precision Ø127mm or 5"

with blank top jaws

DC80-8B model - diaphragm chuck super high precision Ø80mm or 3"

with customized top jaws

DC4-8-Q model - Quick Change (QC) diaphragm chuck Ø101mm or 4", PCD 40mm

DC5-TH 27 model - 5" chuck with the largest thru hole, 27mm