UNIQUE SOLUTIONS

June 14, 2018

VISE VS. PRECISION AIR CHUCK

The following case study reviews the difference between working with a vise vs. using a

two jaw self centering stationary precision air chuck to clamp an odd shape small work piece.

The following workpiece was milled in a CNC machining center. All five walls are done in the first

operation except one.

The second and last operation is to mill the final wall (on the left side). The cycle time is very short, less than 20 second. There are a few options:

It could be done in a vise with a stopper. However, a vise is not an ideal solution time wiseand it also requires manual force to open and close the vise. Besides, the workpiece has to be at one edge and the vise walls might not be parallel to each other applying uneven force along the workpiece wall. Even when clamping two workpieces, one on each side of the vise, it does not guarantee a reliable stopper

A more efficient way and more considerable to the operator’s strength and force

to complete the task is to use a two jaw stationary precision air chuck. The following photo

shows the set up for this operation. The two jaw chuck on its fixture is mounted in the middle

with a stopper. The opening and closing switch is on the right side. The airways are safely secured.

Advantages:

1. Fairly easy set up.

2. Easy and fast clamping and unclamping of the work piece, saves time.

3. Consistent and controlled pressure on the work piece prevents variations.

4. Repeatability of the work piece position within 0.005 mm time after time (each piece will be situated exactly as the previous one).

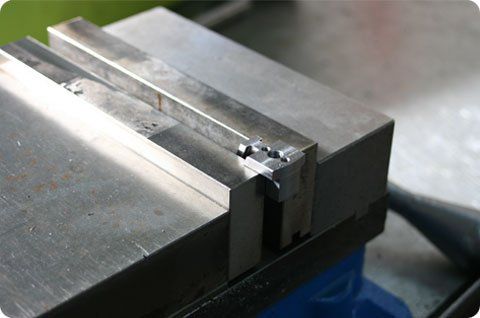

Closer look at the chuck and the work piece. The steel jaws were machined to fit the workpiece.

The operator places the workpiece with the right hand between the jaws and effortlessly

secure clamping with his left hand.

The operator shows his productivity in just a few hours. Using the air chuck saves at least

30% on cycle time.

The process is not so sophisticated. Using the air chuck really saves time and effort.

The operator is very content working with his finger tips vs. using a whole arm.....